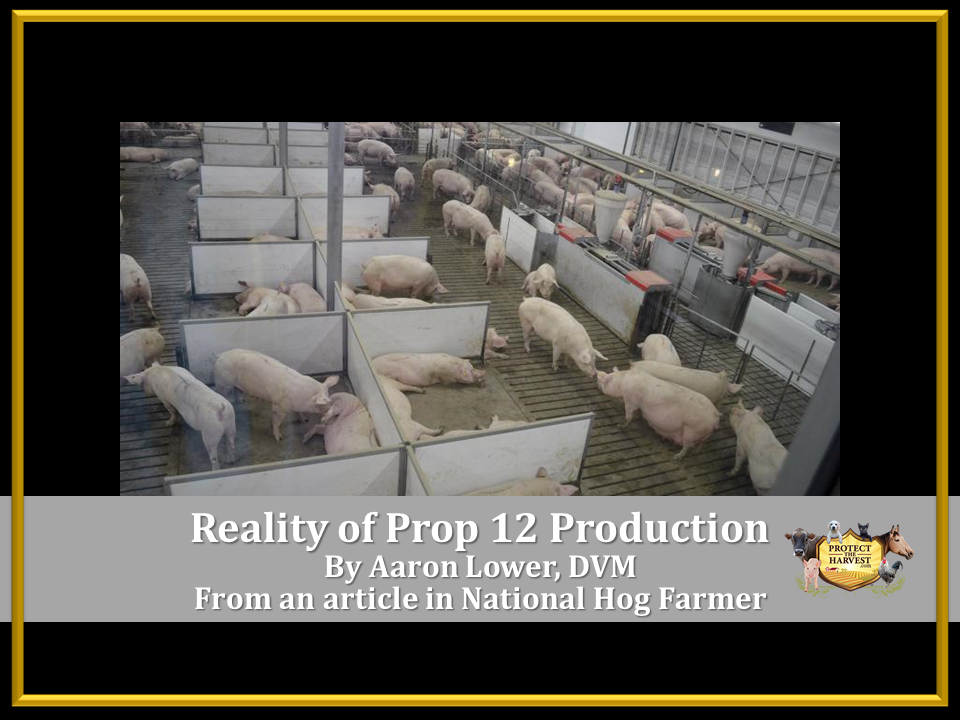

In Farms That Have Implemented Prop. 12 Breeding, it is Taking About Two to Three Hours Per Day to Drop Feed, Heat Check and Release Animals.

By Aaron Lower, DVM, Carthage Veterinary Service

From an article in National Hog Farmer

Just this week we see yet another change in the Proposition 12 implementation! The Superior Court for Sacramento County in California has halted the enforcement of Prop 12 for 180 days after the final rules go into effect. What a high-stakes ride! Hats off to the producers and processors that have plunged forward with the investment of capital and time to be ready by Jan. 1, 2022. All this while we should soon learn if the Supreme Court of the United States will hear the case regarding this law’s potential violation of the Constitution’s Commerce Clause.

We have a few weeks now of Prop 12 implementation in client herds. I would expect you will see another article in this series as we continue to learn and adjust. There are many unknowns in how Prop 12 housing rules will affect long-term production and expectations of “good” breed to wean production. This article is not addressing the validity or reasoning of the law but sharing some of the practical side to implementing Prop 12.

Prop 12 production, as it was intentionally crafted, will have tremendous implications regarding the target production cost for wean pigs from the farm. Rough math, if a farm was to add gestation to maintain farrowing throughput, it would add a minimum of $6 per wean pig. If a farm was to just reduce inventory, it would add roughly $11 per wean pig. Those estimates use optimistic production efficiency numbers and prior to COVID construction inflation.

Farms that do not have on-farm gilt developers make it an easy decision to build a new Prop 12 gestation barn on site. If Prop 12 incentives go away, that barn can become gilt development. For farms that currently have on-site gilt developers, it is best to convert that barn to gestation housing and develop gilts offsite.

In both of these scenarios, it is best flexibility for the facility to move the GDU off-site. The farm needs enough space to grow the gilts to breeding age, breed, and house them through pregnancy check. If farrow rates are going to run in the high 80’s, producers will have enough square footage to bring back those animals at ~6 weeks of gestation. If farrowing rates are going to run in the low 80’s, these farms will need to bring back these gilts home closer to farrowing.

One of the frustrations in the late rule-writing was specifically when a gilt needed to be housed at 24 square feet. Initially, it was written at six months or 182 days of age. In a 5,000 head sow herd with an average breeding age of 224 days, this six weeks of housing at 24 square feet for 50 gilts per week took square footage needs from 2,400 square feet to 7,200 square feet. This has been redefined in December rules published for public comment to when gilts start a “breeding cycle.” Therefore, that additional square footage is now not needed. This delay in rulemaking is frustrating as producers had invested capital in GDU space that is now not necessary.

Designing the breeding area, flow and grouping is going to be an area where we will learn much. I have been surprised how agitated and aggressive these weans sows are through day 7 sows post wean, during their heat cycle. Any person or animal that walks by these pens signals all the sows in the pen to come over to that area, rooting, riding and piling up. These animals are rarely laid out and content. Having full length stalls (free access) that allow securing animals for a few hours per day is going to be best.

In farms that have implemented Prop 12 breeding, it is taking about two to three hours per day to drop feed, heat check and release animals. A clear marking system for breeds is necessary as breeding cards are worthless. Farms are initially trying breeding pens versus a breeding snake. Each wean day goes out to their designated pens and are heat checked and bred in that pen. As they complete their two or three matings and are not in heat, they are removed that day into an early gestation snake. This allows tight breeding ages in those pens, at the expense of mixing sows again. At six days post wean, any wean sows left in the breed pen (late weans) are moved to an opportunity pen. This opens up the pen for the next days wean. The opportunity pen is heat checked daily for breeds. One time per week, that pen’s inventory is reviewed. The farm makes decisions on culling, keeping and PG600.

Post-pregnancy check, animals are regrouped again according to pregnancy status, parity, body condition score and breed date. We will see how BCS is going to work in the various housing systems. Our traditional flow into breeding crates for 40 days has historically allowed us to recover and get body condition consistent before we moved animals out to stanchion or electronic sow feed housing. However, with the change in Prop 12 housing, stanchions may not allow us an opportunity to get body condition satisfactory. ESF may be a more viable option, we will wait and see.

There is much to be learned from Prop 12 breeding/gestation housing from the early adopters. I hope that their risk pays off and have an opportunity to be rewarded for that risk. This industry is innovative, and I am sure will develop best practices to manage the welfare and production of our sows.

Source: Aaron Lower, Carthage Veterinary Service, who is solely responsible for the information provided, and wholly owns the information. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.